-

Glycerin, sugar, ethanol and other ingredients that improve transparency (clarifying agents) are added to the soap body, and stirred in to create the body for Transparent soap. Then, prior to cooling and hardening, pH and volatility are measured and the soap is tested for skin irritation.

-

The frame kneading method is used for Transparent soap. Hot gel-form Transparent soap body is poured into a frame for cooling and hardening. It is important to manage the hardening temperature and time very carefully in order to bring out the beauty of the Transparent soap.

-

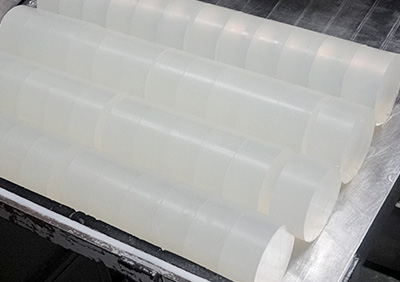

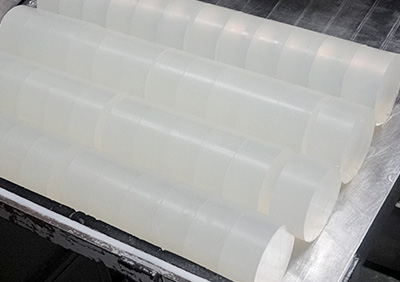

After hardening, the rod-shaped soap is extracted from the frame. From there, it is cut with piano wire (stainless copper wire) and then individually arrayed on a drainboard. The soap is not yet transparent at this stage; a bit of cloudiness remains.

-

Immediately after cutting, the soap is still soft and the outside is very vulnerable to scratching and denting. As a result, seemingly simple tasks like picking the soap up and placing it on the drainboard require the utmost of care. It is a detailed, painstaking, manual process.

-

After drying and maturation, the soap moves to the finishing process. Each piece of Transparent soap is polished by hand. This may seem like a mindless task, but it requires a great deal of skill to bring out the beauty of the Transparent soap, and polishers must be extraordinarily careful about how they hold it.

-

After polishing, the soap is stamped. Stamping is one type of forming process. The soap is warmed to body temperature, and each piece is individually stamped. This is an essential task, not only for bringing out the visual beauty of the product, but for making sure that the form and size of the soap are suited to the hand.

-

From there the soap moves to final testing, checking for pH and volatility, as well as the scratches, deformation and transparency. Only products that pass all tests are shipped and delivered to customers.

MANUFACTURING / Transparent soap

Appropriate raw materials are crucial to highly Transparent soap that is easy on the skin. The fatty acid composition determines the lathering and cleansing force of the soap, and it is obviously an important component, but the proportions of other raw materials are also key, for example, the glycerin and sugar that reduce drying.