-

The soap stands still for 1-2 days after being put in the frame until it cools and hardens. This process is referred to as "soap crystallization." Once the soap is hardened, it is removed from the frame and cut into slabs. A team of two holds the ends of a piano wire, calling back and forth to coordinate their timing as they slice off each slab. From there, the slabs of soap are cut lengthwise and widthwise according to the weight and dimensions of the final product.

-

The cut soap is dried and matured for a period of 7-20 days a drainboard (if non-transparent soap). During this period, the soap gives up its moisture and its crystals solidify. That is why frame kneading method soap is hard and does not easily dissolve.

-

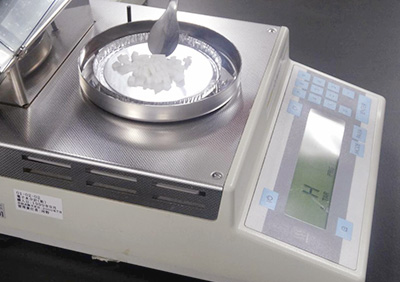

After the drying and maturation period, the soap is tested for volatility. Only soap that satisfies rigorous standards goes on to the finishing process. In the finishing process, soap is packaged and then boxed as the final product for delivery to the customer.

MANUFACTURING / Frame kneading method

High-temperature gel-form soap body flows from the tank into the frame. This is called the "frame kneading method" because the soap is put into a frame before cooling and hardening. Matsuyama uses the frame kneading method for toilet soap (face and body washing), transparent soap (face washing), and solid soap (laundry).