MANUFACTURING

The Sumida factory of Matsuyama Yushi has been making pure soap base with the kettle burning method for more than 70 years. This is a traditional process using natural oils and fats as the main ingredients. It is said that there are only a few companies in Japan that still use this method because it takes time and manpower. The process, which takes four days and approximately one hundred hours to complete, is manualized in the product standards. However, there are some things, such as how to raise or lower the temperature of the oven and how to check the quality of the finished product, that cannot be learned without seeing and hearing the process firsthand. Many things have been passed down from one generation to the next. They also learn to think about how to make it easier for the next person to do their job. This is because manufacturing is like a baton that is handed to people during the manufacturing process. The staff on the shop floor is always working in silence, but they are also encouraged to try new things without sticking to the old ways. We deepen our knowledge and improve our technology to create better products. That's the fun of manufacturing and its value, and we are proud of it. This ethos has been passed down to the Fuji Kawaguchiko Plant.

-

Pot boiling method

The raw materials for soap are natural fat and oil, and caustic soda. Fatty acid, which is a part of oil and fat, bonds with sodium, which is a part of caustic soda, to create soap (fatty acid sodium). The nature of the soap-- how...

-

Skin care

The skin care products area requires particularly strict hygiene management. Before entering the production room, there is a secondary changing room where employees change their shoes and put on clean wear. They wash their hands a...

-

Frame kneading method

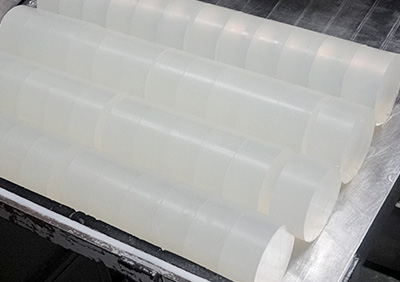

High-temperature gel-form soap body flows from the tank into the frame. This is called the "frame kneading method" because the soap is put into a frame before cooling and hardening. Matsuyama uses the frame kneading method for toi...

-

Milling method

Hot gel-form soap body is dripped onto a cold roller drum, causing a thin layer to instantaneously solidify on the drum's surface. The solidified soap is then automatically raked into a ribbon shape before being sent to the dryer.

-

Transparent soap

Appropriate raw materials are crucial to highly Transparent soap that is easy on the skin. The fatty acid composition determines the lathering and cleansing force of the soap, and it is obviously an important component, but the pr...

-

Liquid soap

Liquid soap uses different oils and fats than solid soap because it must remain in liquid form even at low temperatures. The best fatty acid compositions for liquid soap come from plants. The pot boiling method uses the caustic po...